| Published in the June - July 2002 Issue of Anvil

Magazine

Note: Images and Captions appear at the end of this article. It seems 2002 is the year of the Write-In President, the year of Honoring the American Spirit, the year of the Experimental Non-Overlapping Convention Format. The 2002 American Farrier's Association Convention held in Lexington Kentucky, is a year many of us won't forget. Topping off the AFA Presidential race that almost wasn't, Craig Trnka of Edgewood, New Mexico waged a successful write-in campaign that defeated Andrew Elsbree of Greenville, New York. Ahead under Craig's leadership, in his own words: "The AFA will be going back to horses and practical skills. We are going to stick to horses, because that's where the rubber meets the road." The Convention was held at the Hyatt Regency, which was under remodeling. At times the smell of diesel fuel, fresh paint and the sound of grinding gears and equipment was difficult to endure, but we farriers are a pretty tolerant group to these types of inconveniences, and the show went on. In honor of the men and women defending our country and those lost in the 9/11 tragedies, Don Gustafson of Palo Alto, California sang "America the Beautiful" during the Opening Ceremony as the crowd stood in teary-eyed silence. Don's voice was rich and deep, singing every note full and beautiful. Thus began the 31st Annual AFA Convention in cooperation with the Bluegrass Horseshoer's Association. This year's Convention was the trial of a new format. Instead of overlapping contesting events and lectures, the contests were scheduled from Monday through Wednesday and the lectures from Thursday through Saturday. Only problem was it made for a long trip away from home. Forging Contest The forging and shoeing contest was held at the nearby Lexington Horse Park, with shuttle buses every half-hour from the Hotel. On the bus ride to the Horse Park, I saw impressive entryways with names like Eaton and Cobra Farms, and I looked in to see huge barns and acres of fencing. Once at the Horse Park, I was amazed by the size of the place. The Park itself is over a thousand acres, with miles of white wooden fencing. The contest took place in a huge indoor arena, and the forges were already fired-up for the draft shoe competition when I arrived. What gives contesting its draw? "I enjoy the teamwork," said Alexi Gutierrez of Royal Palm Beach, Florida. "It's more fun to forge with a friend; we learn from each other." Alexi's partner, Bryce Burnett lives over two hours away in Zolfo Springs, Florida, and yet the pair still manage to practice one or two times per week. They compete in warm-ups in Florida and attend clinics together. Alexi enjoys applying what he's learned in contesting to his everyday shoeing and seeing how much better his day-to-day work is. According to Bryce, contesting is also good for his bottom line. "My clients appreciate my skills, and I don't have to worry about charging $40 more than the other guys in my area." Contestant Richard Ducker of Michigan, a competitor since the late 1980's, has this to say: "Contesting keeps us older guys in shape and tuned-up. We feed off of each other, share knowledge, and stay more efficient in our daily work. "Our industry is a `show-me' type of industry with skills handed down from one generation to the next. Before there were all these commercial tools and shoes, guys made all their own stuff. That's what needs to be handed down." Hands On Clinic Thanks to the programs of the American Farriers Association, it is still possible to hand down skills to the next generations of farriers, especially through the Hands On Clinic. California farrier Allan Maraviglia put it this way, "You've got to admire these guys for their dedication and work. People who use only keg shoes get to cheating on the fit, get to using cams and stall jacks and have lost the art of the anvil horn. This is a dying art unless we keep it alive." The Hands On Clinic focused on just that. I watched old-timer Edgar Watson working at the anvil with Roy Verocay of Uruguay, South America. At one point Edgar stood behind Roy like a dance instructor guiding him through specific moves. I stopped and took note of the friendly hum in the air during the Hands On segment, as goggle-clad spectators stood close to watch the masters teaching their age-old craft. Live Shoeing Contest The live shoeing event is music in motion. The stands where I sit are filled to overflowing; intent faces lean over the railing, prying for a closer look. I, too, am drawn into the present moment, into the art form itself. Muscles, sweat, forges, Glowing steel, horses and hammers Dance their magic on the arena floor beneath me. White-coated judges and red-vested stewards Stand goggled watch-like birds of prey- As the contestants, the Barry Bonds' of our industry Fly through their paces in Xtreme fast motion. First comes the soft dull sound of hot steel giving way to productive hammer blows. Then the scraping sound of wire brushes shoot flying embers across the floor Like sparklers on the Fourth of July. Next, the sound changes to crisp pinging As the Anvil Chorus starts tapping, Ringing in the contest's symphony. I am transfixed. Hot steel smites my nose. I watch the hypnotic purple licking flames Of a coal fire surge momentarily, then recede. Fiery orange flames leap from the side ports of the Propane forges, painting heat waves in the air. The contest itself is divided into heats. Each round has sixty minutes to complete shoeing a front foot and making a specimen shoe for the opposite hind foot. The top finishers of the qualifying round compete in reverse order, so the contestant in first place competes in the last heat. The next round of contestants are on the floor Waiting for the whistle to begin. I watch one guy bending, flexing his arms Like a boxer awaiting the bell to fight. Now, he bends over his anvil, one hand on the horn, The other on the heel, in silent meditation. Then whistle blows and his sinewy frame springs into action. I observe the competitors style as they work their craft. They differ from patient slow, even blows To rapid-fire successions of quick taps. Around me in the stands I hear The hushed commentary of the crowd. Then the loud speaker breaks into the orchestration, Jolting me from my mesmerism . . . Shoeing Demonstrations Live shoeing demonstrations included both the AFA Silver and Gold Teams, Draft Horse shoeing in stocks with Dave Harvey, and shoeing the Arabian Show horse with Bob Parks. In the demonstration of our 2001 AFA Silver Team Eric Novaez, Terry Holst, Troy Price, and Roy Bloom showed us how they work together to shoe a horse. Roy Bloom narrated, reminding us not to be too aggressive on the frog or sole during the trim-just take the chalky, dead material. Bring the heels back to the widest part of the frog. Look for the plane of the foot to match that of the frog. Clean out the seat of corn, but don't get too aggressive with the bars. Aim to get the horse to stand underneath himself. Pull the foot forward and clean up any flares on the outside. One man worked on the horse, two worked the forge and anvil together, and the other announced. There were almost no words exchanged among them as they worked; each guy seemed to know just what to do. But they didn't start out with this synchronization; they had to learn how to work together, to watch for subtle signals. Roy Bloom told us about the incredible heat wave that the Team encountered last year at Calgary, where they came in 5th place. The temperature, which started at 95 degrees, climbed to over 120 degrees with all of the fourteen team's forges fired up! This was the Silver team's first competition together, and as the temperatures soared, they were happy to have finished. Practices for the Team were a logistical nightmare, as all four members live in different parts of the country. Roy explained that the Silver Team was formed to let more people have the team experience. Since the Silver Team is on its own financially, getting together to practice required personal sacrifice and commitment. By the way, a decision was passed down at the Board Meeting here in Lexington to eliminate the AFA Sliver Team, so the concentration will be on just one team, the American Farrier's Team. Preparing for the Journeyman Exam Bobby Menker and Dick Becker did a presentation on how to prepare for the Journeyman Exam. It seems many candidates show up to the exam unprepared. Be sure to bring two sets of every tool, in case something breaks-without a backup tool, you're out. And the tools must be sharp. Balance is somewhat subjective. If you have any questions about your horse, point it out to the Examiner and Tester so they can see what type of material you have to work with, such as a high/low horse, for example, or a horse with thrush. Be warned that sometimes the horse you get won't have much foot, so start out wire brushing only, and see if this is enough-you could get into trouble by taking off too much foot! Bob and Richard basically went through the journeyman test guidelines step by step, and then demonstrated on a horse. A video of the lecture is available from the AFA office for those of you preparing for the exam. This would be very helpful in understanding what you will be judged on. Bob offered tips like, after forging your shoe, close your eyes, run your hands over and feel your work; your hands will tell you better than your eyes. Part of the test is efficiency. Time management is critical. Practice putting a limit on your time, and don't worry about being perfect. If you spend too much time you won't pass the test at all. Know that you won't get all ten's, so do your best and move on to the next step. Have your fire on from the start so it is hot and ready for you to be productive. And don't try something new the day of the test. Set up your work area the same way as in your shop at home, so you will be comfortable with yourself and your tools. Marketplace The Marketplace this year seemed to be the year of the plastic shoe, with many new makes, models, and materials available. Why plastic? It seems that the farrier industry is changing, just like all the rest. Dave Piwko of Jumps USA, importer of The Easy Walker shoe from Austria, (www.easywalker.at) explained why plastic is becoming important. "Our shoe is made to work like a horse's bare foot. A bare hoof has the right combination of flexion, slide, and traction. The hoof flexes with each stride, and when stopping, it allows the horse some slide. It doesn't grab and stop abruptly, torqueing joints and tendons." The Easy Walker is made in Austria, and is a result of ten years of research by a dedicated European farrier. The shoe combines two different types of polyurethane for traction, wear and shock absorption. It is designed for working performance horses in all types of disciplines, and has been used and tested by hunters, jumpers, dressage, endurance, carriage and police forces. "The most ideal situation for the horse is to have no shoes at all. The shoe is designed to act like a bare foot to prevent stress and lameness. There is also a therapeutic model with a built in medicine plate. The center of the plate can be cut out to use as a snow shoe." Easy Walker also makes a neat clinching tool called the Easy Rivet for securing almost any plastic or metal shoe. The tool blocks and clinches-tight-with one series of hammer blows, countersinking the nail into the shoe. The shoes can also be glued in place. Then, there is a new style of horse hoof boot, the Old Mac of Australia (www.oldmacs.com). These boots have waterproof uppers attached to a tough plastic sole. Adjustable with Velcro straps, the boots can be used as a medicine boot, as protection for the coronet band during horse transportation, or in lieu of shoes as hoof protection on the trail. Another plastic shoe, the Ultra III (www.plasticspecialties.com) boasts a patent on a different type of plastic: polyethylene. This shoe lasts longer (4-6 resets) than the other plastic shoes on the market, which are made of polyurethane. Invented by plastic designer Steve Bruns of Hutchinson, Minnesota, the Ultra III is designed to be shaped by cold forging: "The more you work it, the better it gets." Polyethylene has a number of attributes that make it ideal as a horseshoe: high tensile and flexural strength (the same flexural resistance as the normal hoof), low coefficient of friction, and high impact shock absorbency. Auction Once again, the Auction showcased unique works of farrier art in addition to products and services. Don Gustafson sang the "Star Spangled Banner" in his deep, tenor voice. Originally, the song was available to the highest bidder, but Lee Green suggested that perhaps everyone should chip in-with that, the crowd spontaneously passed around hats and boxes, and over $900 was collected. Bravo Don and Lee, for the inspiration. Alice Musser of the American Farrier's Journal took on a big project this year. She spearheaded an industry-wide effort to honor farrier Burney Chapman. Alice put out a call to farrier supply shops, manufacturers, farriers and even horse owners to design, stitch and turn in a patch that would be compiled and sewn into a special, one-of-a-kind quilt. Bob Peacock was the lucky buyer for $4,000. Other beloved old-timers such as Hall of Famer Harry Patton of California were also honored with a square, also Jim Linzy, Bill and Bonnie Pieh of Centaur Forge, and Suzanne Willis from Valley Farrier Supply, Oregon. All in all, the Auction brought in over $28,000 this year. Banquet The award banquet found Austin Edens repeating his winning performance as both AFA National Highpoint Winner and 2002 Overall Highpoint Winner. Austin scored four firsts and won first seat on the 2002 American Farriers Team joined by Bill Poor, Troy Price and Richard Becker. John McNerney and Todd Walker are alternates. Bob Jones won the Barbecue Sauce Contest, and Clay Flynn won the Rig Contest. Anatomy Discussion Lab Even with the format this year having the contest being scheduled separate from the lectures, it was still difficult to pick and choose between activities. I, for one, want to see it all, and the anatomy discussion is one of my favorite places to be. This is the nitty- gritty, hands-on round table discussion made possible by the many freeze-dried specimens from Allie Hayes' collection. In addition to discussions on laminitis, medial/lateral balance, high/low feet, club feet, tendons, ligaments and bones, and reading radiographs, this year Allie provided a table just for barefoot trims. Included were specimens trimmed for barefoot by seven different farriers/trimmers: Dr. Ric Redden, Gene Ovnicek, Lyle Bergeleen, KC La Pierre, Dennis Manning, Mike Savoldi, and Dr. Hiltrud Strasser. Facilitated by Dan Bradley of GE Forge, California, the hooves-which were only half-trimmed to show what was removed-had their own stories to tell. It was a great idea to have the feet side-by-side for comparison, and I hope Allie will keep these specimens as an ongoing study. Palmar Foot Pain Dr. Tracy Turner of the University of Minnesota gave a thorough presentation at the AFA Convention in Lexington on diagnosing and treating palmar foot pain in horses. Dr. Turner has found that more than one third of all chronically lame horses fall into this navicular syndrome category." We must change the idea that A + B = C. Let's see what is wrong and where the pain is coming from." Heel pain can be kind of a puzzle. By adding up many clues, we can get a more specific diagnosis and treatment. Rather than lump all palmar pain into one category, Dr. Turner broke navicular pain down into five "foot pain groups." Navicular region pain (coffin joint and bursa), about 50% of the horses. Coffin joint but not bursa pain, 10-15%. The causes of pain include calcification of ligament or bone (caused by torque or stress), several types of bony changes or holes in the bone causing it to lose dynamics, hoof capsule/bony column orientation, medial/lateral balance, and damaged joint surfaces. Treatment Although the treatment of navicular syndrome is as controversial as any other aspect of the disease, Dr. Turner found that correct shoeing is the basis of all treatment. Yet, not all horses should be shod or addressed the same, but need to be assessed individually on a case-by-case evaluation rather than a standard formula. When shoeing corrections are made within the first ten months of lameness, there is up to a 96% chance of success. The longer corrections are forestalled, the slimmer the success rate. When shoeing changes are not made until after one year, the chance of success drops to 56%. Shoeing considerations include: 1) Correct any pre-existing problems of the hoof, such as under-run heels, contracted heels, sheared heels, mismatched hoof angles, broken hoof/pastern axis. 2) Use all weight bearing structures of the foot 3) Allow for hoof expansion 4) Decrease the work of moving the foot. Other therapies may include injections into the coffin joint, the use of drugs to increase circulation (such as Isoxsuprine) some surgical treatments and at last resort, nerve blocking. Good farriery is the foundation of navicular syndrome therapy. It is important to really look at the foot and how it is shaped, how it sits on the end of the leg. Watch how the foot lands and moves, and come up with a shoeing program that best supports the needs of that particular horse. |

|

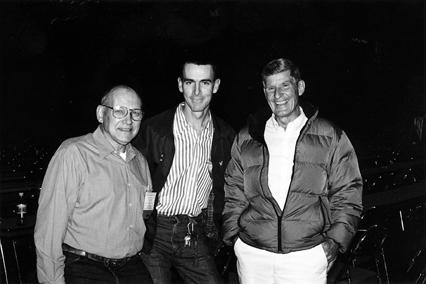

| CAPTIONS 1. Three AFA Presidents Bruce Daniels, Craig Trnka, Walt Taylor |

|

| 2. Park Entrance Sign |

|

| 3. John Brandan's shoeing board display, Market Place |

|

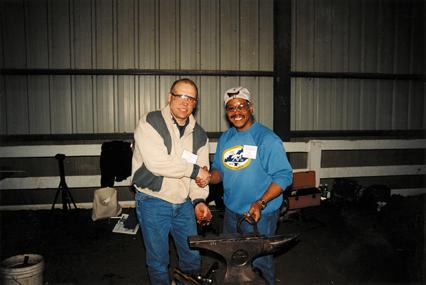

| 4. Perry Hoist, AFA Team Member, King Lamadora -Hands on clinic, lateral concave support shoe |

|

| 5. Alice Musser of the American Farrier's Journal took on a big project this year spearheading an industry-wide effort to honor farrier Burney Chapman with this quilt. The Auction brought in over $28,000. |

|

| 6. Clark Metcalf of Utah made this beautiful rose-studded shoe, which was on display at the Marketplace. There was a patriotic sentiment at the Convention this year as seen in the red, white and blue drapery. Don Gustafson of California sang "America the Beautiful" during the Opening Ceremony as the crowd stood in teary-eyed silence. |

|

| 7. New to the Anatomy Discussion this year was a table just for barefoot trims. Dan Bradley of GE Forge lead the discussion. |

|

| 8. Dr. Tracy Turner of the University of Minnesota spoke on diagnosing and treating palmar foot pain in horses-more than one third of all chronically lame horses fall into this navicular syndrome category. |

|

| 9. The Easy Walker shoe from Austria combines two different types of polyurethane to work like a horse's bare foot. Also shown is the Easy Rivot clinching tool |

|

| 10. Marguerite Therrien of Mustad, Hunter Class: Troy Price (3rd), Austin Edens (4th), Todd Walker (5th), Jim Quick (6th), Mark Milster (2nd), Bill Poor (1st) |

|

| 11. Marguerite Therrien, North American Challenge Cup: Austin Edens (1st), Mark Milster (2nd), Bill Poor (3rd), Jim Quick (4th), Troy Price (5th), Dick Becker (6th) |

|

| 12. Journeyman Class: Troy Price (2nd), Hank Highfield (3rd), Dick Becker (5th), Todd Walker (6th), Bill Poor (4th), Austin Edens (1st), Clint Carlson of St. Croix |

|

| 13. Carlos Lara of Mustad, Mustad Specialty Forging: Mark Milster (3rd), Troy Price (4th), John McNeary (5th), Bill Poor (6th), Jim Quick (2nd), Austin Edens (1st) |

|

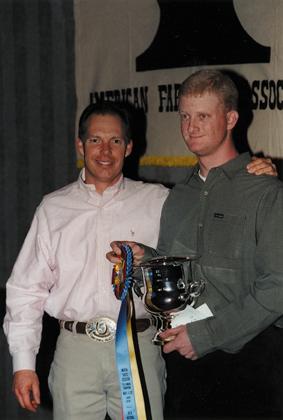

| 14. Bob Pethick, with AFA National High Point Winner: Austin Edens, |

|

| 15. 2002 American Farrier's Team: Troy Price (3rd), Bill Poor (2nd), Austin Edens (1st), Dick Becker (4th), Alternate John McNeary |

|

| Return to the June - July 2002 Table

of Contents

Return to the Farriers Articles Page

|

|