| Published in the March 2000 Issue of Anvil Magazine | |

| 1. Forging a "simple scarf" (a short taper) at the far radiused edge of the anvil. |  |

| 2. The flat side is untouched by the hammer and the corners are slightly chamfered. |  |

| 3. The piece is forged over the horn of the anvil. Stock is 3/16" x 1 1/4". |

|

| 4. "Backing up" the bend on the anvil face. |

|

| 5. The scarf point just touches the parent stock; flat side of scarf faces the stock. |

|

| 6. A combination drift/mandrel is inserted at the far end of the bend. |

|

| 7. The strap is lifted to let the mandrel roll away from the smith. |

|

| 8. The smith lowers the holding hand as he/she "traps" the mandrel with half-face (overhanging) blows. The scarf is up; the loop hangs down. This is a good setup for welding. The hammer is an old three pound Channellock. |

|

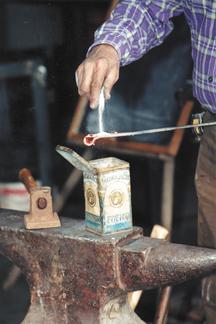

| 9. Twenty Mule Team Borax is applied inside and outside the barrel. |

|

| 10. More Twenty Mule Team Borax |

|

| 11. Welding the barrel with half-face blows at a sweating heat. |

|

| 12. Welding the edge shuts. |

|

| 13. The drift, tapered at both ends, is once again placed through the eye of the hinge. |

|

| 14. The drift is driven into the barrel on the anvil face and then moved to the pritchel hole and driven through. |

|

| 15. Starting to work on the traditional taper at the end of the strap hinge opposite the barrel. |  |

| Return to the March 2000 Table of Contents | |